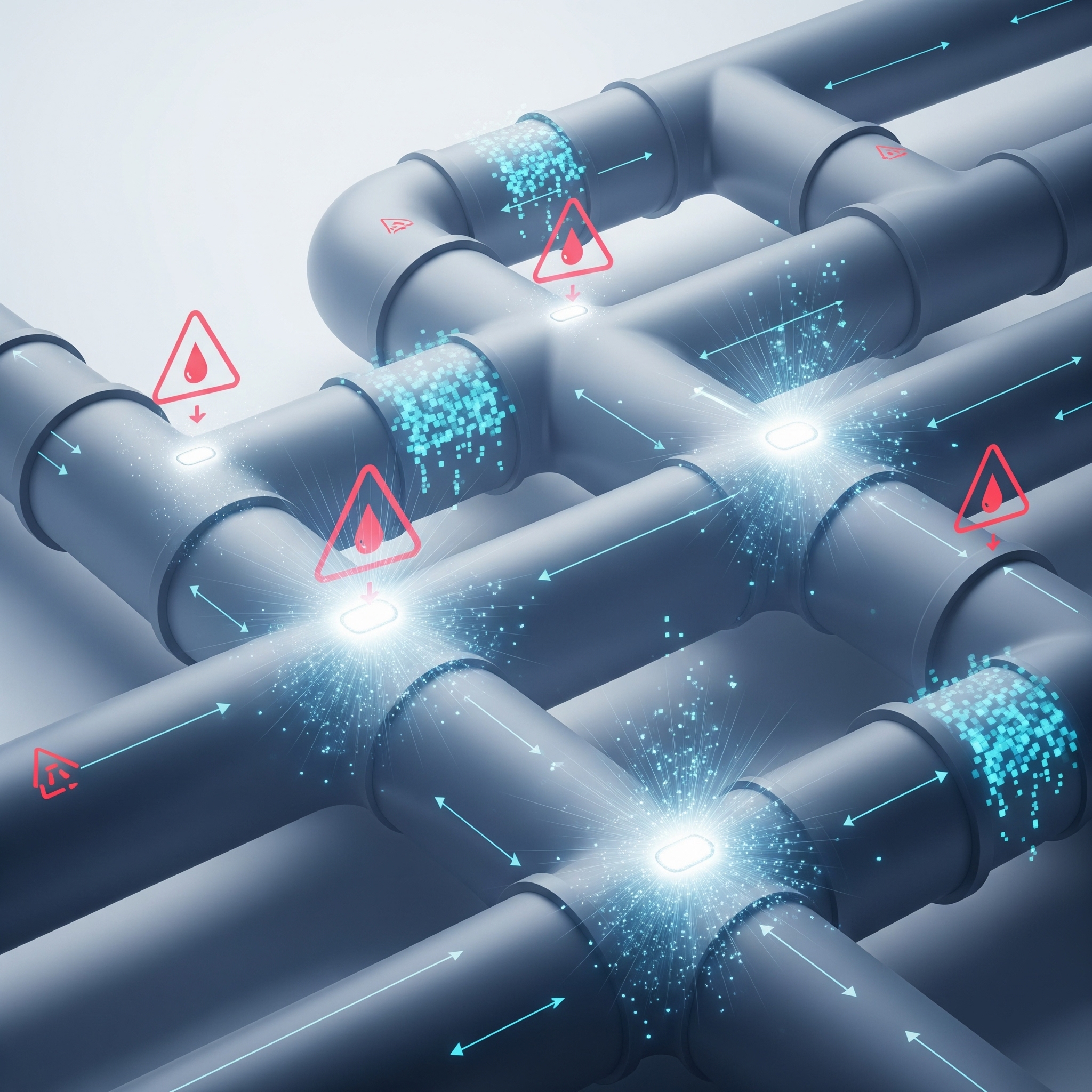

Every business aims for efficiency, but what if your operations are silently bleeding resources? Hidden inefficiencies, often overlooked or simply accepted as “the way things are,” can significantly impact profitability, employee morale, and customer satisfaction. The solution? A thorough Business Process Analysis (BPA).

At Effective Quality Solutions, we understand that true efficiency comes from understanding every step of your operation. BPA isn’t just about finding obvious bottlenecks; it’s about meticulously examining workflows to uncover the subtle “leaks” that drain your bottom line.

What Are These “Hidden Leaks”?

Hidden inefficiencies are often deeply embedded in daily routines. They can include:

- Redundant Tasks: Multiple teams or individuals performing the same task, or unnecessary approval steps.

- Manual Data Entry & Rework: Relying on paper forms or manual inputs that lead to errors, requiring time-consuming corrections.

- Communication Gaps: Siloed departments or unclear communication channels leading to misunderstandings, delays, and duplicated efforts.

- Outdated Technology Use: Using software or systems that are not integrated, inefficient, or underutilized, leading to workarounds.

- Excessive Approvals: Too many layers of sign-off slowing down critical processes.

- Unnecessary Travel or Movement: In manufacturing or logistics, inefficient layouts or routes that add time and cost without adding value.

- Underutilized Talent/Resources: Highly skilled employees performing menial tasks, or expensive equipment sitting idle.

These may seem minor in isolation, but cumulatively, they create a significant drag on productivity and profitability.

How Business Process Analysis Uncovers Them

BPA is a systematic approach that involves:

- Process Mapping: Visually documenting the “as-is” state of a process, step-by-step, including inputs, outputs, decision points, and roles involved. This uncovers discrepancies between documented procedures and actual practices.

- Data Collection & Analysis: Gathering quantitative data (e.g., time spent, error rates, resource utilization) and qualitative feedback (e.g., employee interviews) to identify where delays, errors, and waste occur.

- Identifying Bottlenecks & Waste: Pinpointing specific points where work slows down, resources are wasted, or non-value-added activities are performed. Techniques like Value Stream Mapping help distinguish value-added steps from waste.

- Root Cause Analysis: Going beyond symptoms to understand why inefficiencies exist. Is it a lack of training, outdated technology, unclear roles, or poor communication?

- Designing the “To-Be” Process: Developing improved, streamlined workflows that eliminate waste, optimize resource allocation, and leverage technology more effectively.

The Impact on Your Bottom Line

Uncovering and addressing these hidden inefficiencies directly translates into tangible business benefits:

- Cost Savings: Reduced rework, less waste of materials, optimized labor, and lower operational expenses.

- Increased Productivity: Streamlined workflows mean more output in less time, allowing employees to focus on high-value activities.

- Faster Cycle Times: Products or services reach customers quicker, improving responsiveness and competitive edge.

- Enhanced Customer Satisfaction: Fewer errors, faster delivery, and smoother interactions lead to happier, more loyal customers.

- Improved Employee Morale: Less frustration from inefficient processes, clearer roles, and empowering employees to contribute to improvements.

- Better Decision-Making: Data-driven insights provide a clearer picture of operations, enabling more informed strategic choices.

Effective Quality Solutions works with businesses to perform comprehensive Business Process Analysis, not just to identify problems, but to implement lasting solutions. We help you transform your operations from a source of hidden costs into a driver of profitability and sustainable growth. Don’t let inefficiencies silently erode your profits – uncover them and reclaim your bottom line!